Our history

The Rice family blueberry fields were originally purchased by Willard A. Rice from Samuel Marston on January 19th, 1917. We are now the fourth and fifth generations of Rice family farmers in Lubec, Maine.

The wild blueberry fields have been a touchpoint for our entire family throughout our lives. Our great-grandparents, grandparents, parents, aunts and uncles were proud of their fields, and proud of their contribution to Maine’s economy.

Now operating as Wicked Wild, we’re bringing the fields into the 21st century with mechanical harvesting, irrigation, assisted pollination, use of biochar, and research data targeting the factors that contribute to a profitable harvest – clickable link to “sustainable farming practices”.

Whereas in the past, farmers have been lucky to harvest 4,000 pounds of wild blueberries per acre, healthy fields are now yielding up to 10,000 pounds per acre.

Our berries will be mechanically harvested, then moved to our soon-to-be-built fully mechanized processing facility to be cleaned, sorted, and individually frozen for packaging. Wicked Wild is committed to using sustainable packaging as part of our commitment to a net zero carbon footprint by 2026.

Historical Farming Practices

who we are

Wicked Wild’s farm is typical of many small to midsize Maine wild blueberry farms. Uneven terrain and boulders have historically required hand raking and burning of the fields to reduce weeds and pests. Traditionally, fields were burned either in the late fall or early spring by laying straw harvested from the farm onto the fields. This practice changed to burning with oil, which was expensive and released smoke and pollutants into the atmosphere. Half of the acreage was burned each year and half of the acreage was harvested. Sulfur, which was costly, was occasionally added to lower the soil pH. A robust wild bee population dependably pollinated the blossoms, a critical step for the flowers to become berries. The farmers counted on regional rainfall alone to provide adequate water for the crop.

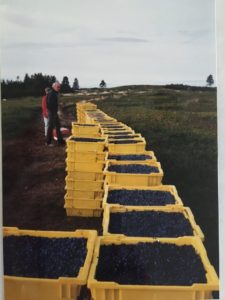

Family, friends and seasonal workers hand raked the blueberries during harvest. The berries were pre-cleaned in the field with a winnower, which removed a large percentage of sticks, rocks and leaves, and then poured into wooden boxes. Each raker’s berry boxes were tallied in the field, and the rakers were paid at the end of each week based on the number of boxes raked. At the end of each day, boxes of berries were hauled in from the fields and trucked to be sold at the local co-op.